WHY CHOOSE MAALACAN CHOPPERS

THE MAALACAN CHOPPER DIFFERENCE

robust construction

The design strength of the Maalacan chopper together with our unrivalled quality of machining means the life of your choppers drums are extended, unnecessary wear and tear is minimised and your blades will wear evenly and last longer.

configuration

Choose from between 2-6 blades, 65mm or 95mm blade length and a hollow shaft, solid shaft or no shaft. For more information please visit the chopper drum page.

even blade wear

Even blade wear can only be achieved with superior machining. Our highly regarded ability to machine tight tolerances allows you to maximise the time between changing blades. As a result our customers can get approximately 7000 tonnes out of one set of blades with even wear in reasonable conditions (left).

drum clearance

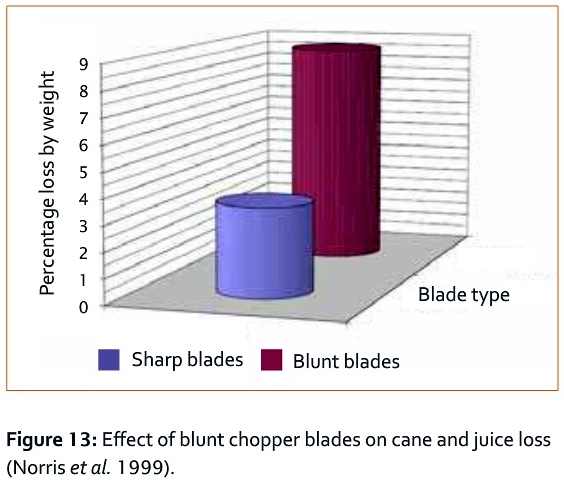

A 65mm drum clearance has been achieved to minimise squashing and juice loss while using less power and pressure to turn the choppers. Maximum clearance is only available with 95mm blades. However, we understand that 65mm blades are more economical, especially when working with stones. Both options are available but drum clearance will differ. The blade is secured in the clamp at a depth of 50mm, leaving 45mm of clear blade for chopping.

longer blade life

Sharpness of the chopper blade and correct overlap is essential for chopping green leaf and trash, and minimising recycling of billets. Sugar Research Australia recommends that blade overlap is kept to a minimum. This is justifiable in ideal conditions. However, the trade-off to the harvester operator is shorter blade life.

By increasing the blade overlap to the length of the bevel, Maalacan choppers have managed to considerably extend blade life while maintaining acceptable billet quality. Longer blade life, no sausages.

View detailed information in the Harvester Parts product brochure.

Download here

hard facing along length of clamp & seat

Hard facing along the length of the clamp and seat is necessary to prevent avoidable wear and tear due to friction between the steel and the impurities in the cane, such as dirt and trash. Longer clamp and seat life can be achieved through the application of hard facing as seen on the clamp below. The hard facing is recessed into the top of the clamp to maintain the maximum chopping clearance.

40mm thick blade seat

The 40mm thick blade seat provides the necessary strength to hold the blade accurately and minimise deflection. It will not flex and is tapered at the top to keep the chopping clearance open. The extra rigidity extends the life of the chopper drum and reduces the number of gussets, opening up the chopping area. The knife will always be held rigid to maintain chopping efficiency.

bolts recessed into blade clamp

The blade clamp bolts are recessed below the surface of the 40mm steel to allow for a thicker, stronger blade seat without protruding into your chopping clearance. All 20mm bolts are easily accessible.

gussets

The use of multiple gussets with 40mm steel is unnecessary. However, two centre gussets have been added for your assurance that blade seat distortion will not occur at the midpoint of the chopper drum. Shorter stiffening gussets are also used but are enclosed by the thrower bars. This adds to the blade seat rigidity and prevents the build-up of dirt and cane fragments wedged between the gussets. Bolt head clearance is also improved.